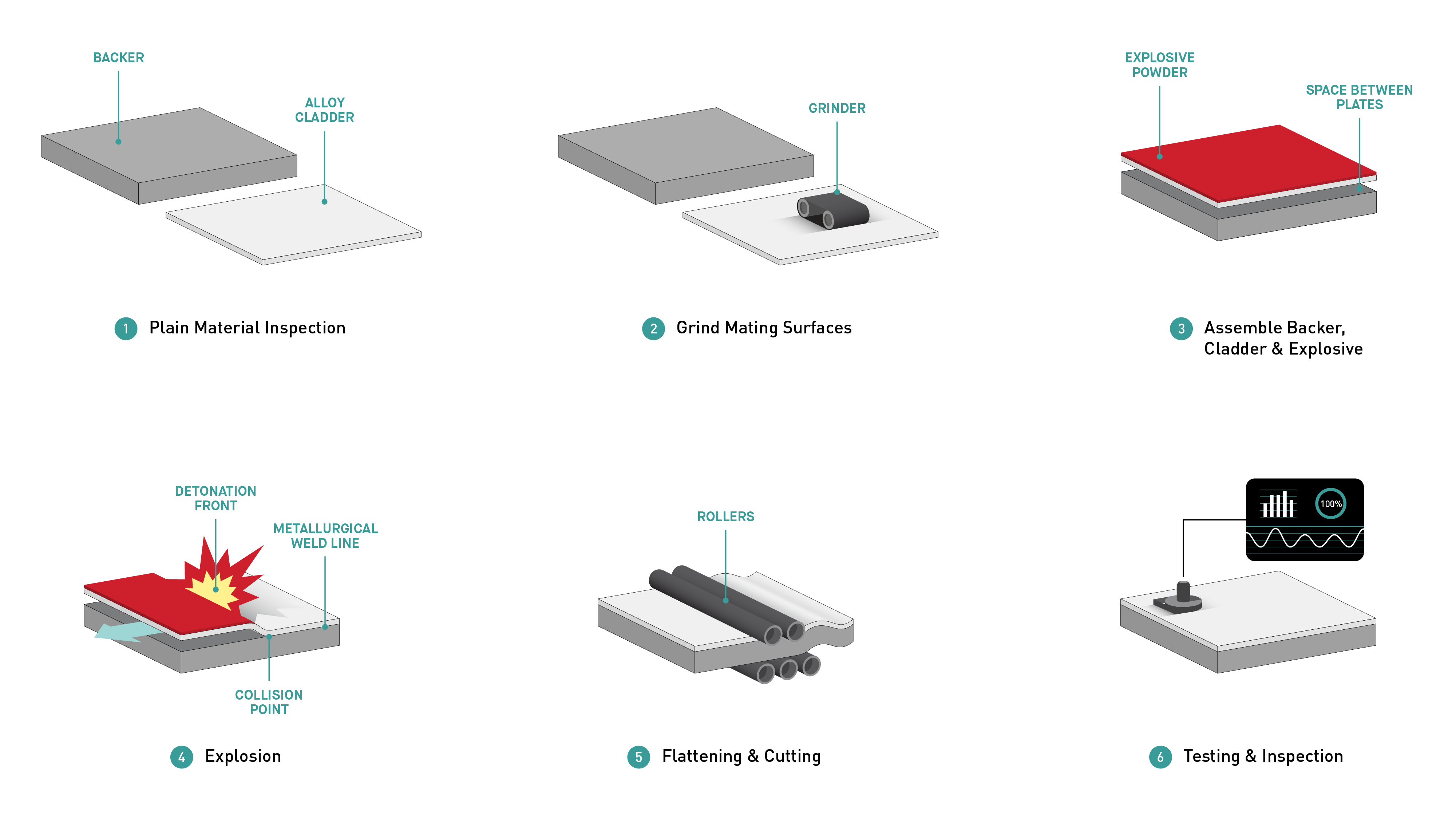

DetaClad™, our proprietary explosion welding process, joins metal plates in a solid state while preserving the mechanical, electrical, and corrosion properties of each metal. By detonating high-energy explosives, our process drives one metal into another, creating a strong metallurgical bond.

Customers often turn to explosion welding to reliably clad steel with alloy metals, such as stainless steel, brass, nickel, silver, titanium, or zirconium. Our explosion-welded applications are made from a wide range of compatible and non-compatible metals. NobelClad is the only company in the world to deliver high shear and high tensile strength across more than 260 metal combinations.

Explosion Welding in 6 Steps

Contact an Engineer

Cladding metals for complex material design and processing challenges is an art form few understand. We are trusted experts in clad metals and applications, and partner with customers, from specification through to delivery and support, to create future clad innovations, today.